Introduction of Qin-Tech New Energy Aerogel Thermal Insulation And Laminating Equipment

-

Introduction of Qin-Tech New Energy Aerogel Thermal Insulation And Laminating Equipment

As the country promotes "Made in China 2025", intelligent manufacturing is becoming more and more important in enterprise production. China's industrial transformation must develop to the high-end industrial direction. Among them, the use of intelligent automation equipment, is also an important milestone in the high-end development of enterprises. Its reflected advantages are: the use of automation equipment, can reduce human resources, reduce the production cost of products; Improve efficiency and increase capacity.

Today, Xiaobian will introduce to you a new energy aerogel insulation and laminating equipment developed and produced by Qin-Tech.

6. Automatic strapping machine can be optional to achieve automatic strapping and packaging, improve the efficiency of manual work and reduce labor.

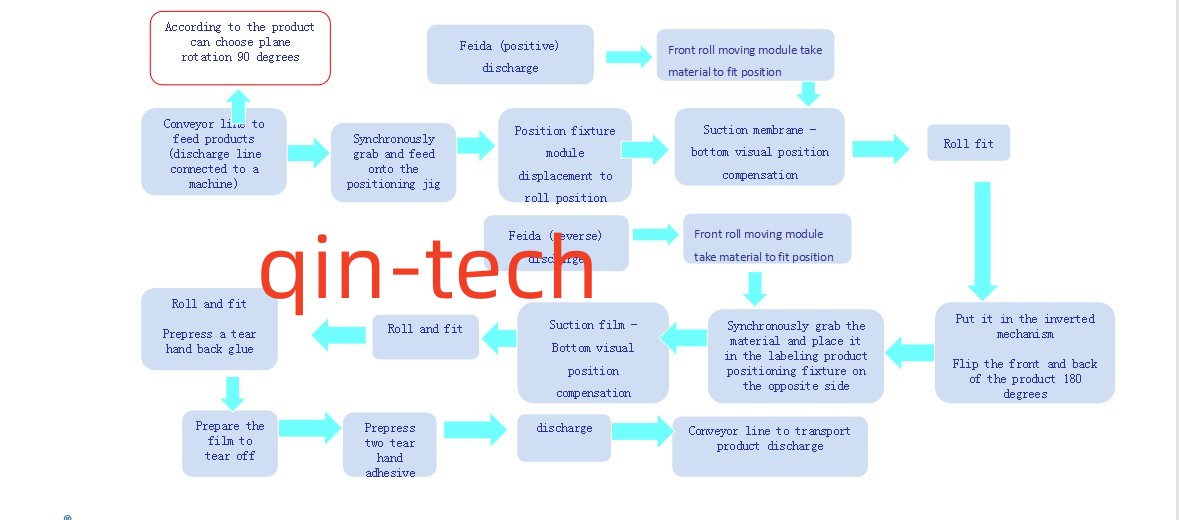

Process flow of new energy aerogel thermal insulation and laminating equipment:

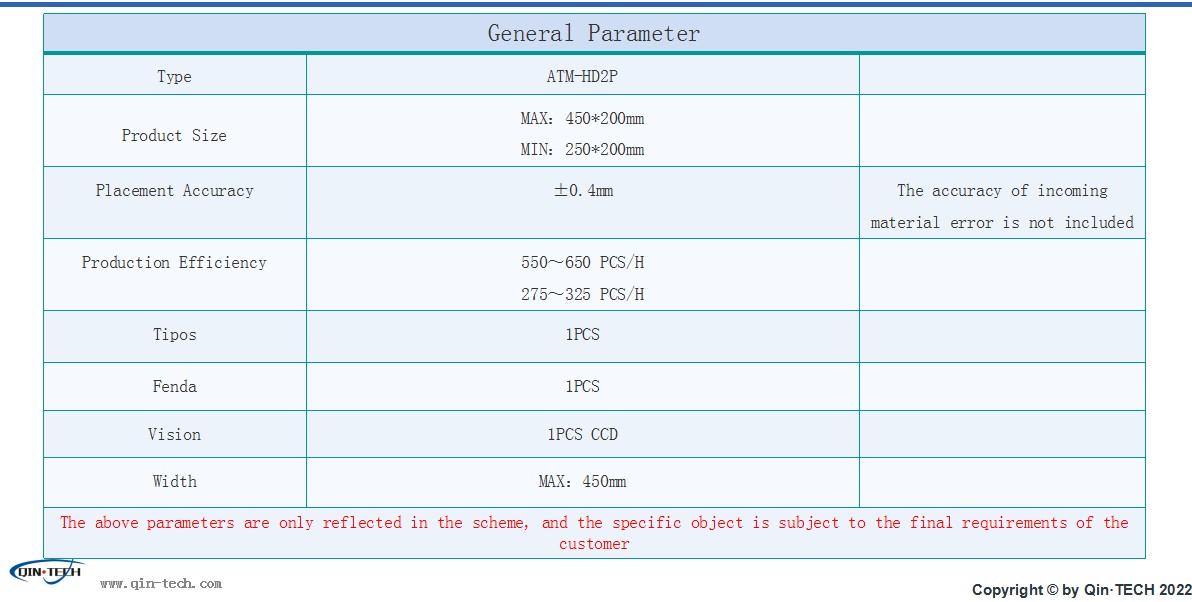

New energy aerogel thermal insulation and laminating equipment parameters:

- In the previous:Don't have!

- The next article:Standard full-automatic paste auxiliary material machine

Related Reading

- ● What are the hazards caused by poor boiler water treatment?

- ● What are the features of a high speed, high precision adhesive backing machine?

- ● Standard full-automatic paste auxiliary material machine

- ● Instructions for the use of high precision automatic adhesive backing machines

- ● The pcb board automatic labeling machine of common problems handling methods

- ● Advantages of online automatic backing machine PK manual backing

- ● How to prevent the reverse osmosis membrane from being contaminated?

- ● Automatic industrial boiler softening water equipment features

- ● Advantages of working with PCB board laminating foam machines

- ● What are the advantages of automatic heat sink adhesive backing machines?